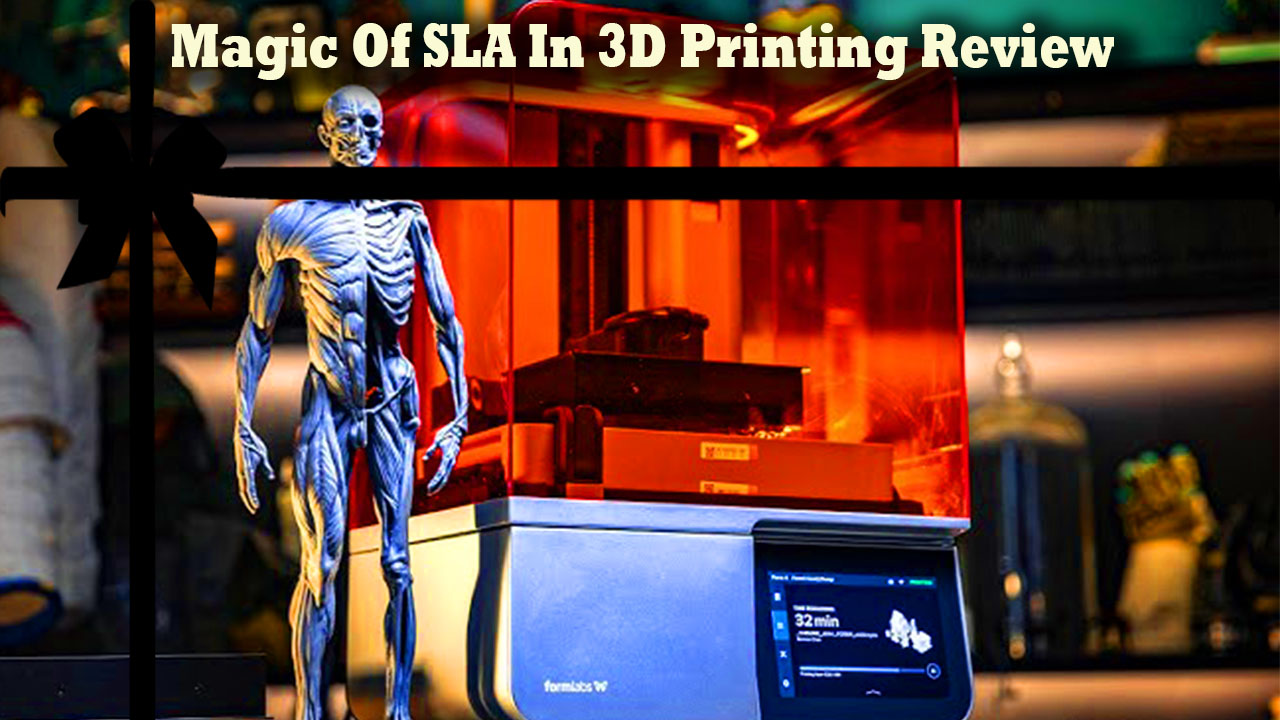

This time I will review SLA in 3D Printing-Welcome to the fascinating world of 3D printing, where imagination meets reality, and innovation knows no boundaries. Among the many techniques, SLA (Stereolithography) stands out as a captivating method that continues to revolutionize the industry. In this comprehensive guide, we embark on a journey to uncover the mystery behind SLA in 3D printing. From its inception to its current application, let’s delve deeper into the layers of this amazing technology.

First of all, let’s get to know SLA in 3D printing

SLA, short for Stereolithography, represents one of the pioneering methods in the field of 3D printing. In essence, SLA uses photopolymerization to convert liquid resin into a solid object, layer by layer. This process involves precise interactions between light and materials, which are regulated with extraordinary precision. Unlike traditional subtractive manufacturing techniques, SLA operates on additive principles, building objects from scratch.

Now!! The SLA process in 3D printing is, a symphony of meticulous steps, each of which contributes to the creation of a highly detailed model. It begins with the preparation of a digital model, usually designed using CAD (Computer-Aided Design) software. This virtual blueprint serves as the basis for creating a physical object. Once the design is, complete, the model will undergo cutting, a crucial step in which the model is, divided into thin layers, like slicing a loaf of bread.

Transitioning to the fabrication stage, the slice model is, transferred to the SLA printer. Inside the printer is, a reservoir of liquid resin, which is, carefully formulated to harden when exposed to light of a certain wavelength. A critical component of an SLA printer, the build platform, descends into the resin, immersing itself layer by layer. Simultaneously, a precisely calibrated UV laser scans the entire surface of the liquid, selectively compacting the resin according to design specifications. As each layer hardens, the building platform rises, gradually revealing the overall three-dimensional object.

Applications Across Industries

Did you know the flexibility of SLA in 3D printing goes beyond borders, it can be applied in various industries. From aerospace to healthcare, automotive to jewelry, SLA technology empowers innovators to realize their visions with unmatched precision. In the aerospace field, SLA facilitates rapid prototyping of complex components, thereby speeding up the design iteration process. Similarly, in healthcare, this technology enables the creation of patient-specific medical devices, tailored to individual anatomy.

In terms of the automotive sector, SLA serves as a catalyst for innovation, empowering manufacturers to prototype complex parts with extraordinary efficiency. Additionally, in the field of jewelry design, SLA opens up new frontiers of creativity, allowing craftsmen to create intricate ornaments with exquisite details. As technology continues to develop, the application of SLA in 3D printing is, poised to expand, reshaping the industry and pushing the boundaries of what is, possible.

Benefits We Can Get From SLA Technology

In terms of SLA’s appeal in 3D printing lies not only in its capabilities but also in its many advantages. Unlike traditional manufacturing methods, SLA offers unmatched precision, enabling the creation of complex geometries with micron-level accuracy. This precision extends to surface finish, with SLA manufactured parts producing a smooth, pristine surface with no imperfections.

Additionally, SLA facilitates rapid prototyping, allowing designers to iterate quickly over multiple iterations without the need for expensive equipment. This agility is, particularly advantageous in an industry characterized by short development cycles and constantly changing design requirements. Additionally, SLA excels in material versatility, accommodating a wide range of resins tailored to specific applications, from flexible elastomers to high-temperature polymers.

Limitation Problems Often Experienced

Now!! Despite its many advantages, SLA in 3D printing is, not without challenges and limitations. One important limitation lies in the size of the objects that can be printed, with SLA printers typically limited by the dimensions of the manufacturing volume. These limitations can create challenges in manufacturing large-scale components or assemblies, requiring alternative manufacturing methods.

Additionally, As I know the post-processing requirements of SLA manufactured parts can be labor intensive, requiring careful cleaning and curing to achieve the desired mechanical properties. Additionally, although SLA offers excellent surface finish, achieving isotropic mechanical properties in all axes can be challenging, especially on highly detailed models with complex geometries.

As technology advances, the future of SLA in 3D printing looks brighter than ever, with continued innovation poised to overcome current limitations and open new possibilities. Advances in materials science are expanding the list of resins available for SLA, meeting a wide range of applications and performance requirements.

Additionally, improvements in printer technology, such as faster drying times and larger build volumes, increase the efficiency and scalability of SLA fabrication. Additionally, the integration of machine learning algorithms and AI-based design optimization tools has the potential to simplify the design process and further improve the performance of SLA-manufactured parts.

In conclusion

The conclusion we can come to is, SLA in 3D printing is, a testament to the ingenuity and innovation that is, driving the additive manufacturing revolution. From its beginnings as an innovative technology to its widespread adoption across industries, SLA continues to push the boundaries of what is, possible, empowering creators and innovators to realize their visions with unmatched precision and efficiency. As we look to the future, the possibilities afforded by SLA technology are limited only by our imagination.

Slug: 3d-printing-layer-lighting-magic-sla-

Meta Description: Dive into the fascinating world of SLA in 3D printing with our comprehensive guide. Explore the complex processes, applications in various industries, advantages, challenges and future perspectives of this innovative technology.