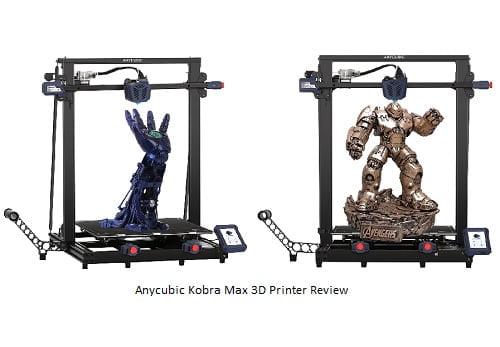

Anycubic Kobra Max 3D Printer full review specification, software-As an AI language model, I don’t have personal experiences or opinions, but I can provide you with a general overview of the Anycubic Kobra Max 3D printer based on information available online.

The Anycubic Kobra Max is, a desktop 3D printer designed for enthusiasts, makers, and professionals looking to produce high-quality prints with ease. It features a large build volume of 300 x 300 x 400mm, which is significantly larger than most other 3D printers in its price range. This allows users to print larger objects or multiple smaller objects in a single print job.

The printer uses Fused Deposition Modeling (FDM) technology, which involves melting and extruding plastic filament through a nozzle to create 3D objects layer by layer. The Kobra Max is capable of printing with a variety of materials, including PLA, ABS, TPU, and PETG, giving users flexibility in their printing options.

The Anycubic Kobra Max features a sturdy metal frame and a dual Z-axis system that provides more stability and accuracy during printing. It also has a filament run-out sensor that alerts users when the filament is running low or has run out, which helps prevent failed prints.

The printer is compatible with a range of software, including Cura, Repetier-Host, and Simplify3D, making it easy to use with a variety of 3D printing software.

Overall, the Anycubic Kobra Max has received positive reviews from users for its large build volume, ease of use, and consistent print quality. However, some users have noted that the printer can be noisy during operation and that the manual leveling system can be time-consuming.

Anycubic Kobra Max 3D Printer Specifications

Sure, here are the specifications for the Anycubic Kobra Max 3D printer:

- Build volume: 300 x 300 x 400mm

- Layer resolution: 0.1-0.4mm

- Nozzle diameter: 0.4mm

- Filament diameter: 1.75mm

- Filament type: PLA, ABS, TPU, PETG, and other filaments with similar properties

- Print speed: up to 100mm/s

- Connectivity: USB, SD card

- Bed leveling: manual

- Operating system: Windows, Mac, Linux

- Input voltage: 110V/220V

- Power consumption: 360W

- Frame material: aluminum

- Printer dimensions: 540 x 530 x 660mm

- Net weight: 13kg

Note that these specifications may vary slightly depending on the specific model or version of the printer.

Layer resolution

The Anycubic Kobra Max has a layer resolution range of 0.1mm to 0.4mm, which is, a common range for FDM 3D printers in its price range. The layer resolution refers to the thickness of each layer that the printer deposits during the printing process. A lower layer resolution (e.g., 0.1mm) can result in higher print quality with finer details, but it may also increase the printing time.

On the other hand, a higher layer resolution (e.g., 0.4mm) can produce prints faster, but the print quality may be lower with less defined details. Ultimately, the layer resolution chosen will depend on the specific application and the desired balance between print quality and printing speed.

Print speed

The Anycubic Kobra Max has a maximum print speed of up to 100mm/s, which is relatively fast compared to other 3D printers in its price range. However, the actual print speed will depend on various factors such as the complexity of the object being printed, the layer height, the material being used, and the printer settings.

It’s worth noting that increasing the print speed can sometimes lead to a decrease in print quality, so it’s important to find the right balance between speed and quality for each print job. In general, a faster print speed can be beneficial for large objects with simple geometry, while slower speeds may be necessary for more complex or detailed prints.

Connectivity

The Anycubic Kobra Max 3D printer offers two main connectivity options:

- USB: The printer has a USB port that allows it to be connected directly to a computer for printing. This allows users to control the printer and send print jobs directly from their computer.

- SD Card: The printer also has an SD card slot that allows users to print files from an SD card. This can be useful for users who don’t want to keep their computer connected to the printer while printing or who prefer to print from a standalone device.

Both of these connectivity options are relatively common among 3D printers, and they provide users with flexibility in terms of how they control and manage their printing jobs. Additionally, the Anycubic Kobra Max is, compatible with a range of 3D printing software, including Cura, Repetier-Host, and Simplify3D, which can be used to generate the necessary G-code files for printing.

Operating system

The Anycubic Kobra Max 3D printer is compatible with multiple operating systems, including Windows, Mac, and Linux. This means that users can control and manage the printer from a computer running any of these operating systems. To control the printer, users can use the provided software or any other compatible 3D printing software that supports the printer’s firmware and file formats.

Additionally, the printer’s SD card connectivity option allows users to print files directly from an SD card without requiring a computer. Overall, the Anycubic Kobra Max is, designed to be compatible with a range of systems and software, making it a versatile and flexible option for 3D printing enthusiasts and professionals.

Input voltage

The Anycubic Kobra Max 3D printer is, designed to operate with a range of input voltages, specifically 110V/220V. This means that the printer can be used with standard household voltage levels in most countries around the world. Users should ensure that their local voltage is compatible with the printer’s requirements before using it to avoid any potential damage or safety issues. Additionally, the printer’s power consumption is rated at 360W, which is relatively low compared to other 3D printers in its class. This can help to minimize energy costs and ensure efficient operation.

Power consumption

The Anycubic Kobra Max 3D printer has a rated power consumption of 360W, which is relatively low compared to other 3D printers in its class. The printer’s power consumption will vary depending on factors such as the print settings, print time, and the type of filament used. However, in general, the Kobra Max is, designed to be an energy-efficient 3D printer.

This can help users to minimize energy costs and reduce their environmental impact. It’s worth noting that the printer should be operated within its recommended voltage range of 110V/220V to ensure safe and efficient operation.

Frame material

The Anycubic Kobra Max 3D printer features an aluminum frame, which provides a sturdy and durable platform for the printer’s components. Aluminum is a popular choice for 3D printer frames because it is, lightweight, strong, and resistant to deformation over time. Additionally, the use of an aluminum frame can help to minimize vibrations and improve print quality by providing a stable base for the printer’s movements.

The Kobra Max’s frame is, also designed to be modular and easy to assemble, which can be beneficial for users who want to make modifications or upgrades to the printer in the future. Overall, the aluminum frame is, an important feature of the Anycubic Kobra Max that helps to ensure reliable and consistent performance over time.

Printer dimensions

The Anycubic Kobra Max 3D printer has a compact and space-saving design, with the following dimensions:

- Printer dimensions (without spool holder): 405mm x 445mm x 520mm

- Printer dimensions (with spool holder): 405mm x 445mm x 605mm

The printer’s small footprint makes it easy to fit into tight spaces, and it’s lightweight design also makes it easy to move around. Additionally, the printer’s modular construction makes it easy to disassemble and reassemble for maintenance or upgrades, which can be beneficial for users who need to move the printer frequently or who want to customize it for their specific needs. Overall, the compact size and lightweight design of the Anycubic Kobra Max make it a versatile and convenient 3D printer for home or office use.

Anycubic Kobra Max 3D Printer Bottom Line

The Anycubic Kobra Max is, a reliable and high-performing 3D printer that offers a great combination of features, quality, and affordability. With a build volume of 300 x 300 x 340mm, it can handle large prints and complex designs with ease.

One of the standout features of the Kobra Max is, its auto-leveling system, which ensures that the print bed is perfectly level every time, resulting in high-quality prints. The printer also has a variety of connectivity options, including Wi-Fi, USB, and an SD card slot, making it easy to transfer files and start printing.

Overall, the Anycubic Kobra Max is, a solid choice for anyone looking for a reliable and versatile 3D printer that won’t break the bank. Its ease of use, large build volume, and high-quality prints make it an excellent option for both beginners and experienced users alike.

Anycubic Kobra Max 3D Printer Preparing Files

To prepare files for printing on the Anycubic Kobra Max 3D printer, you will need to follow these steps:

- Create or download a 3D model: There are many 3D modeling software options available, including free ones such as Tinkercad and Blender. You can also download 3D models from online repositories such as Thingiverse.

- Save the file in the correct format: The Anycubic Kobra Max 3D printer accepts files in STL, OBJ, and AMF formats. Make sure to save your 3D model in one of these formats.

- Slice the file: Slicing is, the process of converting the 3D model into a set of instructions that the printer can understand. You can use slicing software such as Cura, PrusaSlicer, or Simplify3D to slice your model and generate a G-code file.

- Transfer the G-code file to the printer: You can transfer the G-code file to the Anycubic Kobra Max 3D printer via USB, Wi-Fi, or an SD card.

- Set up the printer: Make sure the printer is, properly set up, with the print bed level and the filament loaded and ready to go.

- Start the print: Use the printer’s touchscreen or your computer to start the print job. The printer will begin to follow the instructions in the G-code file and create your 3D model layer by layer.

- Monitor the print: Keep an eye on the printer while it’s printing to make sure everything is going smoothly. If you encounter any issues, such as the print detaching from the print bed, you may need to adjust the print settings or make other adjustments.

With these steps, you can easily prepare your 3D models for printing on the Anycubic Kobra Max 3D printer.

Anycubic Kobra Max 3D Printer Software

The Anycubic Kobra Max 3D printer can work with a range of software options for preparing and slicing 3D models. Here are some of the popular software options that you can use with the printer:

- Cura: Cura is, a free and open-source slicing software that is, compatible with many 3D printers, including the Anycubic Kobra Max. It is, easy to use and offers a range of features, including customizable print settings and support for plugins.

- PrusaSlicer: PrusaSlicer is, another free and open-source slicing software that is compatible with the Anycubic Kobra Max. It is, known for its advanced features, such as customizable supports and advanced infill options.

- Simplify3D: Simplify3D is, a popular commercial slicing software that supports the Anycubic Kobra Max. It offers a range of advanced features, such as customizable support structures and the ability to control multiple printers simultaneously.

- Tinkercad: Tinkercad is, a free and user-friendly 3D modeling software that is, great for beginners. It allows you to create 3D models quickly and easily and supports exporting files in STL format for slicing.

- Fusion 360: Fusion 360 is, a professional-grade 3D modeling software that is, great for creating complex designs. It offers advanced features, such as parametric modeling and assembly modeling, and supports exporting files in STL format for slicing.

In addition to these software options, the Anycubic Kobra Max also comes with its own proprietary slicing software, Anycubic Slicer, which you can use to prepare and slice your 3D models.

Anycubic kobra max vs plus

The Anycubic Kobra Max and Kobra Max Plus are both 3D printers from Anycubic, but they differ in several key ways.

- Build volume: The Kobra Max Plus has a larger build volume of 400 x 400 x 450mm, compared to the Kobra Max’s build volume of 300 x 300 x 340mm. This means that the Kobra Max Plus can handle larger prints and is, better suited for printing bigger objects.

- Bed leveling: While both printers have automatic bed leveling, the Kobra Max Plus has an upgraded version that uses a 25-point matrix instead of the Kobra Max’s 16-point matrix. This allows for more precise bed leveling and better print quality.

- Filament runout sensor: The Kobra Max Plus comes with a filament runout sensor that detects when the filament is, running low and pauses the print job to prevent wasting material. The Kobra Max does not have this feature.

- Connectivity: The Kobra Max Plus has more connectivity options, including Wi-Fi, Ethernet, USB, and an SD card slot, while the Kobra Max only has USB and an SD card slot.

- Price: The Kobra Max Plus is, generally more expensive than the Kobra Max due to its larger build volume and additional features.

In summary, the Kobra Max Plus offers some key upgrades over the Kobra Max, including a larger build volume, more precise bed leveling, a filament runout sensor, and more connectivity options. However, it also comes with a higher price tag. Ultimately, the choice between these printers will depend on your specific needs and budget.

Anycubic kobra max vs vyper

The Anycubic Kobra Max and Vyper are both 3D printers from Anycubic, but they have several differences in terms of features and specifications.

- Build volume: The Anycubic Vyper has a larger build volume of 245 x 245 x 260mm, compared to the Kobra Max’s build volume of 300 x 300 x 340mm. This means that the Vyper can handle larger prints and is, better suited for printing bigger objects.

- Print speed: The Vyper has a faster print speed than the Kobra Max, with a maximum print speed of 300mm/s, compared to the Kobra Max’s maximum print speed of 150mm/s. This means that the Vyper can complete print jobs more quickly.

- Touchscreen: The Vyper has a larger and more advanced touchscreen interface compared to the Kobra Max, which makes it easier to navigate and control the printer settings.

- Filament sensor: The Vyper has a filament sensor that detects when the filament is running low and pauses the print job to prevent wasting material, while the Kobra Max does not have this feature.

- Connectivity: The Vyper offers Wi-Fi and Ethernet connectivity options in addition to USB and SD card connectivity, while the Kobra Max only has USB and SD card connectivity options.

- Price: The Vyper is, generally more expensive than the Kobra Max due to its larger build volume and faster print speed.

In summary, the Anycubic Vyper offers some key upgrades over the Kobra Max, including a larger build volume, faster print speed, advanced touchscreen interface, filament sensor, and more connectivity options. However, it also comes with a higher price tag. Ultimately, the choice between these printers will depend on your specific needs and budget.

Anycubic kobra max fdm 3d

Yes, the Anycubic Kobra Max is an FDM (Fused Deposition Modeling) 3D printer. FDM is a 3D printing technology where a thermoplastic filament is melted and extruded through a nozzle to create layers of material that build up to form a 3D object. FDM is one of the most popular 3D printing technologies and is widely used for producing prototypes, functional parts, and even finished products.

The Anycubic Kobra Max uses FDM technology to create 3D prints by melting and extruding filament from a heated nozzle onto the build platform, layer by layer. The printer is compatible with a range of thermoplastic filaments, including PLA, ABS, PETG, TPU, and more. The Kobra Max also comes with a heated bed, which helps to improve print adhesion and prevent warping of the printed object.